When it comes to testing and analyzing electronic components, precision and accuracy are paramount. That’s where LCR meters come into play. These specialized instruments are designed to measure the electrical properties of passive components with exceptional precision. Today we will explore what LCR meters are, their applications, and how they differ from digital multimeters (DMMs).

What Are LCR Meters?

LCR meters are electronic instruments tailored for the measurement of three fundamental electrical characteristics: inductance (L), capacitance (C), and resistance (R). These components are the building blocks of electronic circuits, and knowing their electrical properties is crucial for circuit design, quality control, and troubleshooting.

Where Are LCR Meters Used?

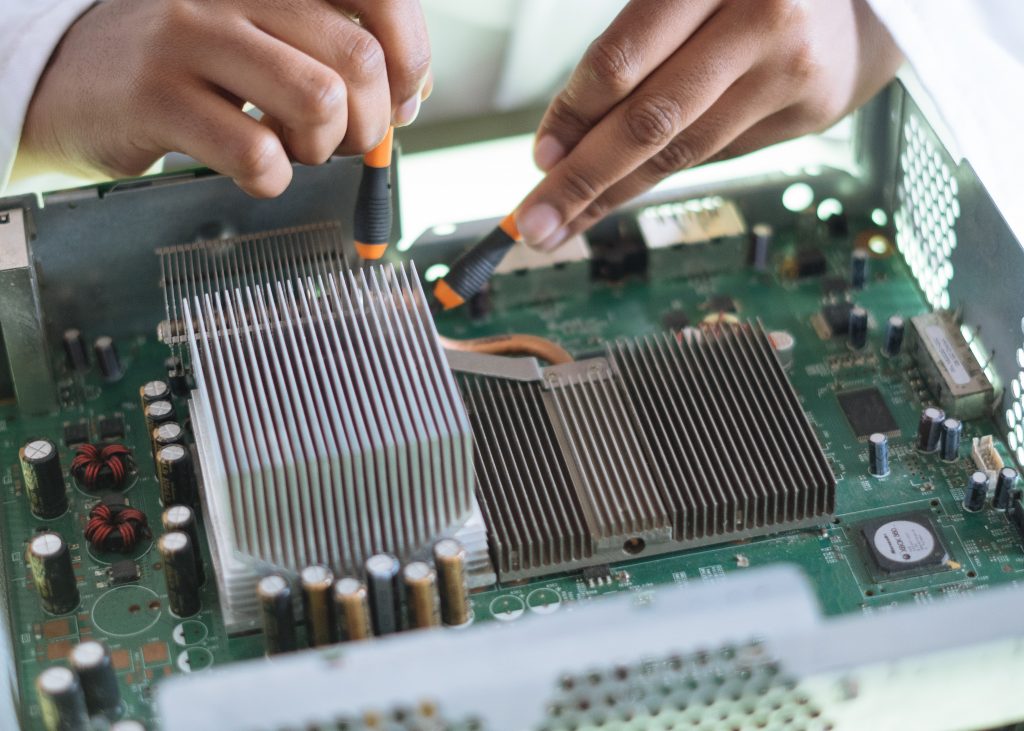

Electronic Component Testing

LCR meters are the go-to tools for characterizing and testing passive electronic components, including capacitors, inductors, and resistors. Engineers and technicians use LCR meters to ensure these components meet specified electrical parameters.

Circuit Design and Analysis

During circuit development and testing, LCR meters help select and verify components that match the desired inductance, capacitance, and resistance values. This ensures circuits perform as intended.

Quality Control

In manufacturing, LCR meters play a vital role in quality control. They identify faulty or out-of-spec components, ensuring that only components meeting specific criteria are used in production.

Troubleshooting

When diagnosing electronic circuits, LCR meters can pinpoint faulty passive components causing problems in the circuit.

What is the Difference Between LCR Meters and Digital Multimeters?

1 ) Measurement Range and Precision:

LCR meters are specialized instruments offering high precision and accuracy within their specified measurement range for inductance, capacitance, and resistance. The Agilent 4285A is a great example of a precision LCR meter.

DMMs are general-purpose instruments that can measure a wide range of electrical parameters, but their precision for inductance and capacitance measurements is often limited compared to LCR meters.

2 ) Frequency Range:

LCR meters can measure components across a range of frequencies, making them suitable for analyzing components used in various applications.

DMMs typically operate at low frequencies and are less suitable for measuring inductance and capacitance at higher frequencies.

3 ) Specialized Functions:

LCR meters, such as the Agilent 4263B, often provide specialized functions like measuring dissipation factor (DF), quality factor (Q), and equivalent series resistance (ESR), which are critical for evaluating the performance of capacitors and inductors.

DMMs do not typically offer these specialized functions for passive component analysis.

4 ) Application Focus:

LCR meters are specifically designed for passive component testing and analysis, making them indispensable in these applications. For example, the Agilent 4294A is a precision impedance analyzer that has 1 mHz of resolution.

DMMs are versatile tools for general electrical measurements, suitable for a wide range of tasks but less specialized for passive component analysis.

In conclusion, LCR meters are specialized instruments tailored for measuring the electrical characteristics of passive components. Their precision and specialized functions make them invaluable in electronic component testing, circuit design, and quality control. On the other hand, digital multimeters, while versatile, lack the precision and specialized capabilities of LCR meters in the realm of passive component analysis. Choosing between the two depends on the specific tasks and requirements at hand, but for those working with passive components, an LCR meter is an essential tool in their arsenal.